Custom PP/PC/ABS Plastic Auto Accessories by Injection Molding

Basic Info.

| Model NO. | WF_JF |

| Weight | Customized |

| OEM Service | Yes |

| Process | Plastic Injection Molding |

| Packing | Wooden Cases or Carton |

| MOQ | 10-100PCS |

| Free Sample | Yes |

| Logo Printing | Customized |

| Custom Made | Yes |

| Shipping Port | Qingdao |

| Export Markets | Global |

| Transport | by Sea or Air |

| Place of Origin | China |

| Technics | Plastic Injection |

| Part Type | Plastic Parts |

| Item | Plastic Parts |

| Transport Package | Plywood Box |

| Specification | SGS |

| Trademark | OEM |

| Origin | Weifang City, Shandong Province, China |

| HS Code | 7326199000 |

| Production Capacity | 50000PCS/Month |

Packaging & Delivery

Package Size 50.00cm * 40.00cm * 60.00cm Package Gross Weight 5.000kgProduct Description

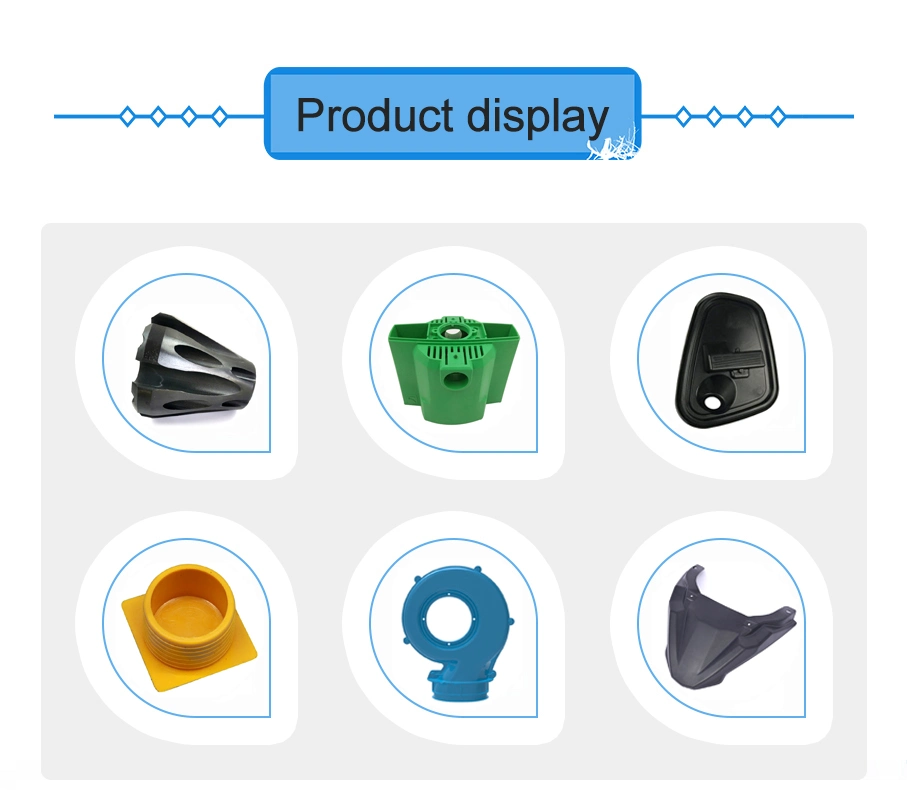

Custom PP/PC/ABS Plastic Auto Accessories by Injection Molding

Our service:

We provide comprehensive turn-key solution based on our indutry clients needs which including:product design,prototyping,mold making,mass production,assembly,packing and shipping service.

Product range | Producr design,mold design, mold making and produce plastic parts |

Processing Craft | Mold fabrication, Injection etc; |

Material | ABS,BMC, SMC, AS,PVC,Nylon(PA),PP,PC,PE,POM,PS,HDPE,TPE,TPU etc |

Surface finish | Polishing finish,Texture Finish,Glossy Finish,Electroplating,Painting,Slik print,Rubber Painting etc |

Color | RAL/PANTONE color |

Mold Standard | DME,LKM,FUTA,HASCO etc. |

Mould Base | as per customer's requirement |

Tolerance | 0.01~0.1mm |

File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

Quality Control | Quality Control |

Inspection | IQC, IPQC,FQC,QA |

Application | All kinds of plastic injection parts being used in a variety of industrial application |

Processing program Our processing has a variety of processing, such as lathes, milling, grinding, boring, drilling, cutting, etc.,to provide you with a multi-faceted service.

| Item | Description |

| 1.Mould material | P20,718H,45#,STAVAX ESR S136,H13,2316,2083,2344 |

| 2.Hardness of steel | vacuum quenching ,nitride,HRC41-47, HRC46-50,HRC60 |

| 3.Inserts / Slider steel | H13 (DIN.1.2344),tempered with HRC46-50 |

| 4.Mould spare parts | H13 (Din 1.2344),tempered with HRC40-45,nitrited with HRC60-62 |

| 5.Mould base | LKM,HASCO |

| 6.Mould cavity | Single / Multi |

| 7.Runner system | Hot / Cold |

| 8.CAD centre for data formats | IGES,X_T,STP & DWG,etc |

| 9.Plastic material | ABS,PC,PE,PP,PS. |

| 10.Mould life | 80000- more than 1000000 |

| 11.Delivery time | 4-8 weeks |

| 12.Terms of payment | T/T, Paypal, Western Union and so on |

Our Services

1.Product Design,Structural Optimization,Process Optimization. 2.Mold Making,Plastic Molding Parts,Casting Parts,Machining Part. 3.Manage Project,Control The Delivery and Quality of Products. 4.Arranging the Transportation,Customs Clearance and other Matters for You.

We offers comprehensive custom plastic injection molding services to a wide range of industries. From low volume work to high volume production runs, we have the expertise and facilities to meet our customers' contract manufacturing needs. We offer two shot, sandwich and insert injection molding as well as micro and gas assist molding. We have both 10K and 100K clean room manufacturing facilities for those customers in the medical, pharmaceutical, food, beverage and electronics industries. Our comprehensive plastic injection molding abilities include machines with clamping forces from 18 to 3,000 tons, allowing us to produce nearly any plastic part including micro parts, thin-walled parts, and large components that require multiple shots.We can source and mold any grade of material from typical commodity grade plastics, to engineering, functional, and structural grade materials in a variety of colors and formulations. In addition to injection molding, we offer many secondary services including sonic vibration, RF welding, hot stamping, etching, printing, plating, and packaging. Our manufacturing processes are highly automated, which allows us to run a precise and efficient production floor with minimal overhead costs. These capabilities allow us to provide fast and cost competitive manufacturing services to our customers without sacrificing precision and quality.

Advantages: 1. Competitive price. 2. Strict quality control system. 3. Quick mold making and delivery. 4. Advanced equipment, excellent R&D teams. 5. Professional technicians and rich experienced workers.

Quality First,Price Best,Service Foremost! We assure you of our best services at all times! If you are interested in any of our products, please send message to us through below approach!